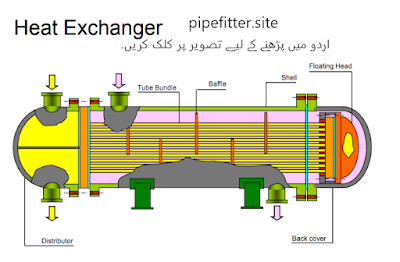

Shell:The shell is the part of a shell-and-tube heat exchanger that is on the outside. It fits around the tubes and supports the structure. It keeps the inside parts safe from external forces and makes fluid flow easier.

Tube bundle:A shell-and-tube heat exchanger has tubes, which are empty tubes that one of the fluids moves through. They let heat move from one fluid to another and are usually made of strong materials like titanium, copper, or stainless steel that can handle high temperatures and pressures.

floatin head:One of the tube sheets can move or "float" inside the heat exchanger. This is called a "floating head." This arrangement allows for different thermal expansion between the tubes and the shell, which lowers stress and the chance of damage to the equipment when temperatures change. People often use floating head heat exchangers in places where temperatures are likely to change a lot, like in high-pressure or high-temperature processes.

back cover:The back cover protects the heat exchanger's rear from dirt, particles, and environmental toxins, protecting its interior components.The back cover may be insulated to reduce heat loss or gain from the heat exchanger's rear, enhancing thermal efficiency. Access panels, locks, and warning signs on the rear cover may restrict unauthorised access to interior components and maintain heat exchanger safety.

gasket:In a plate of heat exchanger, gaskets are bendable seals that are put between the plates to keep fluid from leaking and make sure the seal is tight. Most of the time, they are made of rubber, polymers, or synthetic plastics, which are chosen based on how well they work with the fluids and conditions of use.

tube side inlet:The tube side inlet in a heat exchanger is the point where a fluid enters the tubes, marking the start of the heat transfer process. It is crucial for efficient heat transfer and optimal performance of the heat exchanger, especially in shell-and-tube systems where one fluid flows through the tubes and the other around them.

shell side inlet:The shell side inlet in a heat exchanger is the point where fluid enters the shell side, typically containing a larger volume of fluid than the tube side. It serves as the entry point for fluid flowing around the tubes, which can be heated or cooled depending on the application. Proper positioning and design are crucial for efficient heat transfer.

tube side outlet:The tube side outlet is where fluid leaves a heat exchanger after the heat has been transferred. It's normally at one end, and the temperature and state of the fluid rely on things like flow rate, intake temperature, and heat transfer efficiency.

shell side outlet:In a heat exchanger, the shell side outlet is where the fluid leaves the shell side, which is the cover that goes around the tubes. It is linked to pipes or ducts and moves liquids to the next phase in the manufacturing process. For proper fluid flow and best heat transfer performance, the shell side outlet must be placed and designed efficiently.

saddle:It supports and stabilises the exchanger's cylindrical shell with a curved or U-shaped bracket. Saddles are welded or fastened to the shell and installed on a base or foundation for weight distribution and alignment. In large-scale industrial applications where stability and structural integrity are crucial, they help preserve heat exchanger integrity and operation.

tube sheet:One thick plate is at each end of the stack of tubes in a shell-and-tube heat exchanger. These are called tube sheets. As well as keeping the tubes in place, they seal the area where the fluid streams from the tubes and the shells meet.

Baffles:Baffles are internal devices positioned inside the shell of a shell-and-tube heat exchanger. They disrupt the flow of fluid to promote turbulence and enhance heat transfer efficiency by increasing the mixing of the fluids.

Plates:Plates are thin, flat parts that are stacked on top of each other to make the core of a plate heat exchanger. They have a lot of surface area so heat can move between the fluids, and they are often curved or etched to make the fluids move around and make the heat transfer work better.

Fins:Fins are extended surfaces attached to the outer surface of tubes or plates in some heat exchanger designs, such as finned tube heat exchangers. They increase the surface area available for heat transfer and improve heat transfer efficiency by enhancing convective heat transfer.

channel head vs distributor:

Channel Head: An important part of a heat exchanger is the channel head, which controls the flow of fluid into and out of the tunnels and makes sure that the heat is spread equally across the heat exchanger. It has holes for joining fluids and is usually found at the ends or sides of plates.

Distributor: A distributor is a part of a plate heat exchanger that makes sure that fluid flows properly through all of the plates by spreading it out over the heat exchanger's surface area. This stops bypass flow and makes heat movement more efficient. Fluids can move more easily through distributors because they make the fluid more unstable and mixed. Most of the time, they are on the side of the heat exchanger where fluid enters it.

In short, both the channel head and the distributor help to control the flow of fluid inside a heat exchanger. The channel head controls where the fluid enters and leaves the exchanger, while the distributor makes sure that the flow of fluid is evenly spread across the surface area of the exchanger, especially in plate heat exchangers.

In conclusion,

Heat exchangers consist of several complex components that work together to efficiently transfer thermal energy between fluids. Understanding the functions of these parts is essential to designing, operating and maintaining heat exchangers in various industrial processes and applications.

Comments

Post a Comment